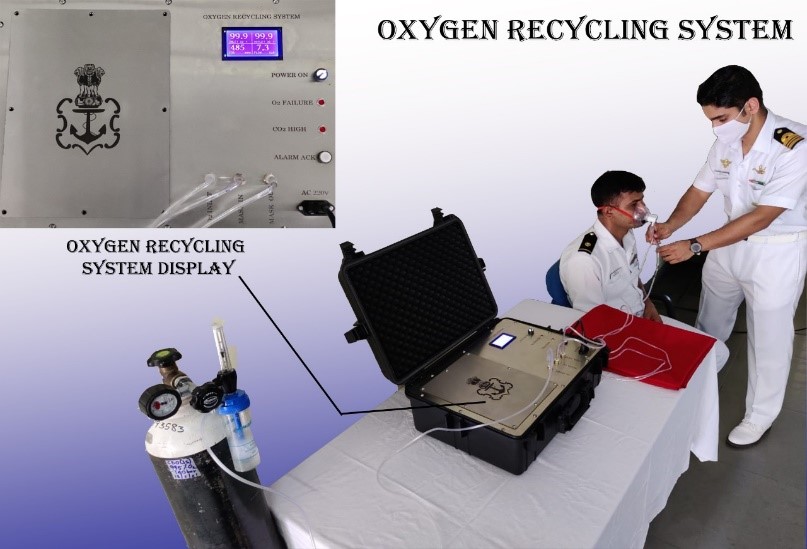

Oxygen Recycling System designed by the Indian Navy to mitigate the current oxygen crisis

Amidst the second wave of COVID-19, the Diving School of the Southern Naval Command of the Indian Navy has conceptualised and designed an ‘Oxygen Recycling System’ (ORS) to alleviate the existing Oxygen (O2) shortages. The Diving School has expertise in this area as the basic concept is used in some of the diving sets used by the school. Earlier, a similar idea on a miniaturised lab model was demonstrated to the Hon’ble Prime Minister during the Combined Commanders Conference at Kevadia on 06 Mar 21.

The ORS is designed to extend the life of the existing medical O2 cylinders two to four times, using the fact that only a small percentage of O2 inhaled by a patient is actually absorbed by the lungs, the rest being exhaled into the atmosphere along with carbon-dioxide (CO2) produced by the body. This exhaled O2 can be re-used, provided the exhaled CO2 is removed. To achieve this, the ORS adds a second pipe to the patient’s existing O2 mask, which sucks out the air exhaled by a patient using a low-pressure motor. Both the mask inlet pipe (for O2) and the mask outlet pipe (for exhaled air) are fitted with non-return valves to maintain a positive pressure and unidirectional flow of gases at all times to ensure the patient’s safety against dilution hypoxia. The exhaled gases, mainly CO2 carbon dioxide and O2, are then fed into a Bacterial Viral Filter and Heat and Moisture Exchanger Filter (BVF-HME filter) to absorb any viral contaminants. After viral filtration, the gases pass through a high-grade CO2 scrubber with a High Efficiency Particulate Air (HEPA) filter, which absorbs CO2 and other particulates, allowing enriched O2 to pass through unaffected. The enriched O2 from the scrubber is then pumped back into the inhalation pipe of the patient’s face mask, thereby increasing the flow rate of O2 to the patient, and reducing the use of O2 from the cylinder.

The air flow in the ORS is maintained by a medical-grade pump fitted ahead of the CO2 scrubber, which ensures a positive flow, facilitating comfortable breathing by the patient. Digital flow meters monitor the flow rate of O2, and the ORS also incorporates inline O2 and CO2 sensors with automatic cut-offs, which stop the ORS in case O2 levels drop below the normal limits, or the CO2 percentage exceeds normal limits. However, this cut-off does not affect the normal in-flow of O2 from the cylinder, thereby allowing the patient to continue breathing easily, even if the ORS stops due to the cut-offs or for any other reason.

The first fully operational prototype of the ORS was produced on 22 Apr 21 and underwent a series of in-house trials and design improvements at the Southern Naval Command, with third-party observers from ISO certified firms. Thereafter, on the directives of NITI Aayog, the system underwent detailed analysis and assessment by a team of specialists at Sree Chitra Tirunal Institute for Medical Sciences and Technology (SCTIMST) at Thiruvananthapuram. The team of specialists at SCTIMST found the concept and design of the Oxygen Recycling System feasible, and also suggested a few additional modifications. An ‘Initial Evaluation Certificate’ was accorded to the ORS on 18 May 21 by the Director, SCTIMST. The system is now being progressed for clinical trials in accordance with existing guidelines, which are expected to be completed expeditiously, after which the design will be freely available for mass production in the country. All components used in the ORS are indigenous and freely available in the country.

The overall cost of the ORS prototype has been capped at Rs. 10,000/- against an envisaged saving of Rs 3,000 per day due to the recycling of O2. Besides substantially enhancing the existing O2 capacity in the country, the ORS can also be used to extend the life of O2 cylinders used by mountaineers/ soldiers at High Altitude, for HADR operations and onboard naval ships and submarines.

The ORS has been designed by Lieutenant Commander Mayank Sharma of Diving School. The system’s design has been patented, and an application to this effect has been filed by the Indian Navy on 13 May 21.